Safety, quality and cost efficiency

Our entire product range is backed with a comprehensive line of support services, product application, research and development, quality control procedures and an intense focus on the requirements and expectations of our customers.

We have a dedicated export department and global advisory service which operates in all major industries across 6 continents, providing support in Africa, and the Middle East, Australia, Latin America, North America, Asia and Europe.

Mechanical power transmission demands high standards of safety, quality and cost efficiency.

Medway Power Transmission are leaders in industrial power transmission research and development, and offer a unique range of products to meet today’s stringent and ever increasing requirements.

Medway’s product range includes belts and pulleys, chains and sprockets, flexible and rigid couplings, weld-on and bolt-on hubs, taper bushes and adaptors, and motor slide bases.

Our range of industrial belts include, V- belts, Micro V-belts, Ribbed belts, and Timing belts.

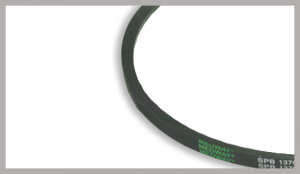

Classical V-Belts

Traditional V-Belts are manufactured with cross-sections Z, A, B, C & D sections with a range of over 500 lengths currently available. V-Belts for industrial use are designated both to RMA standard e.g. A52, where the letter designates its cross-section and the number corresponds to a nominal internal length in inches and to DIN standard e.g. 13x1320Li, where the first number denotes the width in mm, and the second number is the internal length in mm. MEDWAY V-belts have specially treated jackets to give superior anti-static, heat and oil-resistant properties and are static conductive to ISO1813.

Automotive V-belts

Energy saving, higher performance thanks to their flexibility. MEDWAY

Automotive V-belts with a higher performance level have a longer service life. Special designs with Raw edges that allow higher slipping resistance even when they are working with low installation tensions.

Maximum resistance to the action of heat and oils. High antistatic properties used in automotive applications and conforming to ISO1813.

Part numbers are identified by 3 letters (e.g.AVX) the belts cross section and a 2 digit number (e.g.10)the belts top width and a 3 or 4 digit number which represents the belts length in mm. AVX10x800 etc.

Agricultural V-belts

3L, 4L & 5L cross section v-belts provide energy saving and high performance, a premium v-belt ideally suited for clutching application. Length stable kevlar corded (cotton covered) provides fewer take-ups and length adjustments. Longer life coupled with high heat and oil resistance.

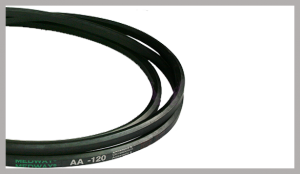

AA, BB & CC cross section hexagonal v-belts are flexible in the direction

of motion, rigid in transverse direction and designed for use in serpentine

agricultural applications involving multiple pulley arrangements.

MEDWAY hexagonal belts are identified by 2 letters stating their cross section (e.g. AA) and by a number (e.g. 105) which represents the nominal

pitch length in inches. AA105 etc.

Variable speed belts

Our range of Variable Speed V-Belts includes belts conforming to ISO R 1604, they are designated by e.g. the letter W followed by a number

e.g. 16 which is the belts width in mm. This is followed by a number

e.g. 500 which corresponds to the pitch length Lp in mm. Belts not covered by the ISO standards are designated by a code consisting of a set of 3 numbers e.g. 22 which denotes the belts top width followed by e.g. 8 which denotes the belts thickness and e.g. 1000 which denotes the belts inside length Li in mm, therefore e.g. 22x8x1000.

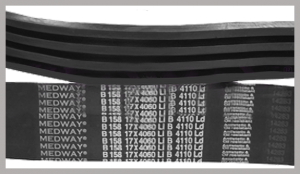

Banded V-belts

Banded V-Belts & Wedge Belts are sets of belts assembled together. Besides incorporating all of the features of standard belts, the belts are joined together to form a band gives the following additional features; no flapping during abrupt load variations, no possibility of turning over and are ideal in high vibration applications. Part numbers are designated by letters standing for their cross-section, e.g. SPB followed by a number e.g. 2000 which specifies the belts pitch length, followed by e.g. /4 which specifies the number of bands.

V-link belting

V-belt Link belting offers a fast alternative to a V-Belt or Wedge Belt in an

emergency break down situation, due to the ease in which the belts length can be adjusted to suit any application. Also used as preferred belting product in applications where an endless belt can not be fitted without an expensive machine breakdown as it can be threaded into place and connected in situ without the need for shafts and bearings to be dismantled.

Wedge V-belts

Wrapped Wedge Belts are designated by letters standing for their cross section, e.g. SPA followed by a number e.g. 1600 which specifies the belts

pitch length Lp in mm. Due to their high power ratings savings can be made over classical V-Belts, smaller pulley diameters and reduced numbers of belts and be incorporated into more compact drives.

Wedge Belts are produced to BS3790, DIN 7753 and AFOR T 47-117

standards. They are manufactured in the cross-sections SPZ, SPA, SPB and SPC in a range of over 400 lengths.

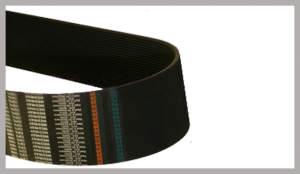

Micro V-belts

High Performance Micro V-Belts in endless construction and with triangular ribs running along the length of the belt, the entire power is transmitted by a single belt. Drives can be reduced in size when compared with traditional V-belt drives as smaller pulleys can be used that will transmit equal or higher loads thereby reducing space requirements and cost. Higher ratios and increased belt speeds can also be achieved.

Part numbers are identified by a 3 or 4 digit number (e.g. 1321) which

represents the nominal length in mm, a letter (e.g. J) the cross section and a 2 digit number (e.g. 08) the number of ribs. 1321J08 etc.

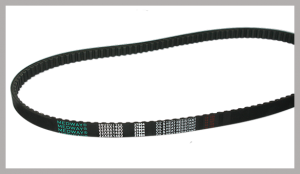

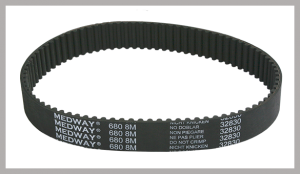

HTD timing belts

The new HTD parabolic profile is deeper than the equivalent competitors

standard tooth profile. The increased depth and sturdiness of the tooth results in an increased torque transmission capability and reduced interference during meshing. The recess in the top of the tooth allows local deformation of the belt when meshing with the pulley, and this contributes to the ability to absorb shock loads

and reduced interference during meshing. Other benefits include a reduction in transmission noise, an increase in tooth jump resistance, an increase in power transmitted and an increase resistance to tooth shear. Part numbers are identified by a 3 or 4 digit number (e.g. 960) which represents the pitch length in mm, a number and letter (e.g. 8M) th

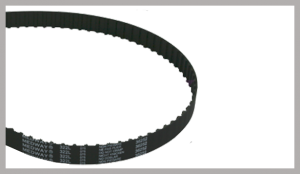

Imperial timing belts

MEDWAY imperial timing belts are available with either single or double

sided teeth, are manufactured using the most advanced technology

available. Trapezoidal tooth profile and Polychloroprene teeth offer

accurate meshing with the mating pulleys and this contributes to the ability to absorb shock loads and reduced interference. Fibreglass reinforcement for minimal elongation and a nylon fabric protects the tooth surface. Part numbers are identified by a 3 or 4 digit number (e.g. 900) which represents the pitch length in inches i.e. 90”, 1 or 2 letters (e.g. H) the belts pitch and a 2 or 3 digit number (e.g. 200) the belts width i.e. 2” for example

900H200.

PU timing belts

MEDWAY metric pitch timing belts are available with either single or double sided teeth, are manufactured using the most advanced thermoset moulding processes available. The high grade polyurethane gives excellent abrasion and shear resistance, combined with a variety of graded steel cords, ensuring high strength is maintained.

Features include consistent dimensional stability, low pre-tension, low noise, high abrasion resistance, low maintenance, high flexibility, linear speeds up to 80 m/sec. good resistance to heat with a working temperature range of -25’C to +80’C and a good resistance to oils, fats and greases. Part numbers are identified by a letter and number (e.g. T10) which represents the belts pitch, followed by 3 or 4 numbers (e.g. 810) the belts length in mm, and a 2 digit number (e.g. 50) the belts width, for example T10-810-50.

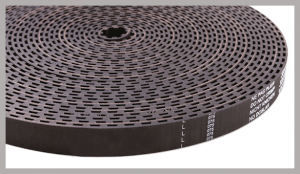

Open ended timing belts

MEDWAY Open Ended Timing Belts are manufactured in both rubber and thermoplastic polyurethane giving superior wear and abrasion resistance, specifically suitable for linear drives, accurate positioning and reversal drives. A high load capacity, low maintenance costs and very low noise levels, make open ended belts a perfect alternative to chain or cable linear drives. Features include; Consistent dimensional stability, low pre-tension, low noise, high abrasion resistance, low maintenance, high flexibility, linear speeds up to 80 m/sec, high precision linear positioning.

Open ended rubber and polyurethane timing belts are produced in both

straight and spiral cut options and are available in the following cross

sections; 3M, 5M, 8M, XL, L, H, T5 & T10.